ZJK Industrial Co. Ltd.

ZJK Industrial and Chaince Digital Announce Strategic Partnership for U.S.-Based Precision Components R&D and Manufacturing Base Serving AI & Semiconductor and Other Industries, with Expected Investment Plan of Up to $200 Million, Advancing the “Made in America” Strategy

ZJK today announced that it has entered into a strategic cooperation framework agreement with Chaince Digital Holdings Inc. (NASDAQ: CD) (“Chaince Digital”) to jointly build a precision components R&D and manufacturing Gigafactory in the U.S. serving the AI, semiconductor, electronics, automotive and other industries.

Under the framework agreement, the parties plan to invest in multiple projects through a combination of self-owned capital and external fundraising, with total investment expected to reach up to US$200 million. This initiative aims to strengthen the U.S. high-end manufacturing ecosystem and further support the “Made in America” strategy.

A Next-Generation R&D and Manufacturing Platform for Global Technology Leaders

The planned Gigafactory will focus on high-value precision and hardware components, excluding restricted semiconductor segments such as wafer fabrication, chip design, or advanced packaging. Target product categories include:

• AI end-device and intelligent hardware components;

• Semiconductor equipment parts and structural/thermal components;

• liquid-cooling components and high-performance thermal modules components;

• New energy vehicle components;

• Smart wearable device components; and

• Other consumer electronics components.

The proposed project will be carried out in accordance with applicable laws and regulations.

Delaware Joint Venture to Operate the U.S. Gigafactory

ZJK and Chaince Digital will establish a Delaware-based joint venture (“Delaware JV”) to serve as the operating entity for the proposed precision components R&D and manufacturing Gigafactory serving AI, semiconductor and other advanced technology industries in the U.S.

U.S. Localized Management Team to Lead Execution

The collaboration aims to advance the “Made in America” strategy by leveraging the strengths of both parties in manufacturing, market resources, management expertise, and capital capabilities.

A U.S.-based management team will be formed, consisting of senior executives with extensive experience in traditional manufacturing, consumer electronics supply chains, and automotive manufacturing at major U.S. companies.

The Delaware JV seeks to become a leading U.S. high-end manufacturing supplier for the AI hardware, semiconductor equipment, electric vehicle, and consumer electronics sectors, delivering high-value hardware and precision components under the vision of “Made in America, Increasing Market Share in America.”

Chaince Securities Officially Appointed as ZJK’s Five-Year Capital Markets Strategic Advisor

According to the framework agreement, Chaince Securities, LLC (CRD 10590), a U.S.-licensed broker-dealer and subsidiary of Chaince Digital, will serve as ZJK’s capital markets strategic advisor for the next five years. Key areas of focus will include:

• Capital markets strategy;

• Financing for the proposed U.S. Gigafactory and ZJK’s ongoing public company financing initiatives; and

• Support for the establishment and operation of ZJK’s U.S. headquarters.

Executive Comments

ZJK Industrial stated:

“This partnership will significantly strengthen ZJK’s manufacturing footprint in the U.S., enabling us to serve global technology customers with greater efficiency while advancing Made in America initiative. Our strategic goal is to establish localized U.S. manufacturing capabilities within the next five years.”

Wilfred Daye, Chief Strategy Officer of Chaince Digital, stated:

“We are pleased to partner with ZJK to build a world-class precision components R&D and manufacturing platform serving the AI, semiconductor and other industries. Chaince Digital will leverage its strengths in capital markets, digital technology, and industrial resources to fully support the development of the proposed U.S. Gigafactory project.”

ZJK Industrial Co., Ltd. Reports Financial Results for the First Six Months of Fiscal Year 2025

ZJK today announced its unaudited financial results for the first six months of fiscal year 2025 ended June 30, 2025.

We are pleased to report strong performance for the first half of fiscal year 2025. Thanks to the consistent efforts of our entire team and the firm execution of our deliberate and robust strategy, revenue increased by 52.21%, accompanied by a 7.09% growth in gross profit margin during the period. Specifically, our sales volumes of hardware products, including turned parts, screws and stamping parts, grew strongly by 33.13%, 45.59% and 177.47%, respectively. This momentum was driven by rising market demand for higher precision and quality, together with our agile pricing strategies that balanced both price increases and reductions across different product categories.

For detailed financial reports, please click on the link to view.

ZJK Industrial Co., Ltd. Reports Financial Results for the First Six Months of Fiscal Year 2025

sec.gov/Archives/edgar/data/1941506/000173112225001278/e6859_ex99-1.htm

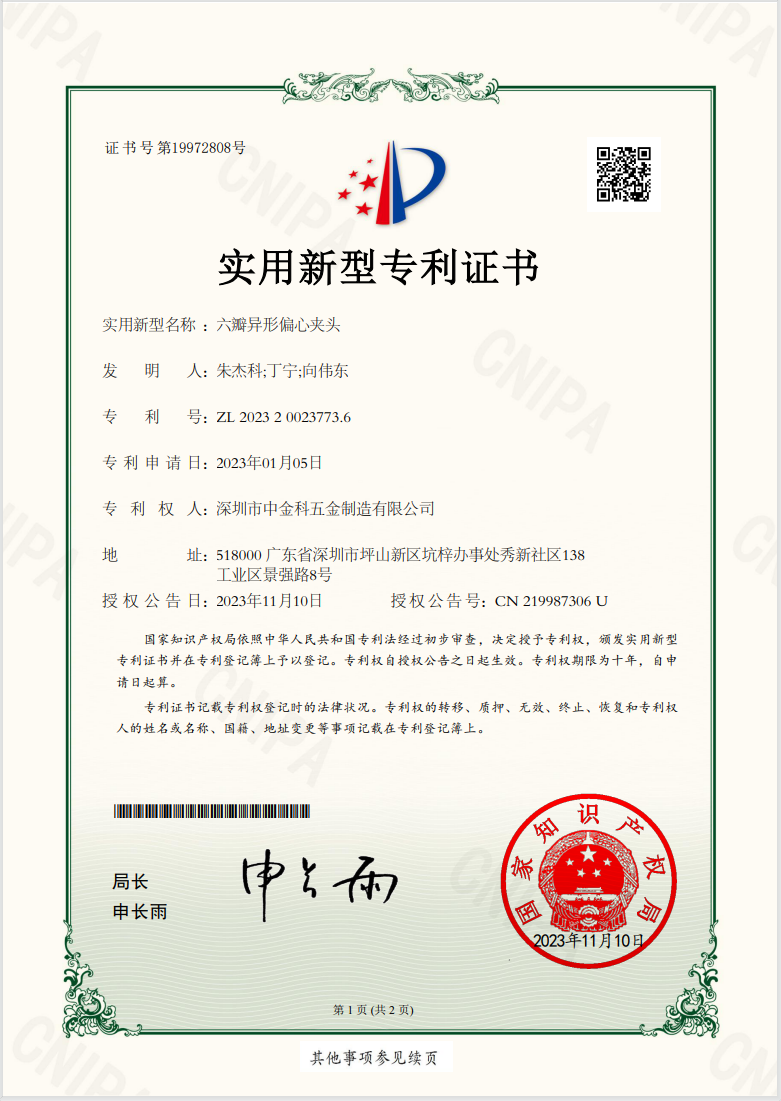

ZJK Industrial Boosts Production Efficiency for AI Servers and Robotics components with Patented Six-Flap Eccentric Chuck

ZJK announced the integration of a six-flap eccentric chuck into its production line for machining irregularly shaped, eccentric, and thin-walled workpieces. This advanced chuck significantly improves production efficiency, reduces the risk of workpiece deformation, and minimizes reliance on operator alignment skills.

The core advantage of this six-flap eccentric chuck lies in its ability to efficiently, precisely, and conveniently clamp challenging workpieces that are difficult to secure using traditional clamping methods.

Patented by the China National Intellectual Property Administration with a 10-year term, the chuck features a unique eccentric structure that automatically adapts to the geometric center of a workpiece. It is especially effective when the geometric center (or center of gravity) does not coincide with the rotational center, or when handling workpieces with non-standard contours, such as non-circular, polygonal, or bossed/recessed surfaces. This structural innovation significantly reduces or even, in certain applications, eliminates the need for manual alignment, greatly improving clamping efficiency and consistency. It is particularly well-suited for batch processing of workpieces that share the same design but may exhibit minor variations from casting or forging.

Furthermore, the chuck distributes clamping force evenly across the contact area, especially when the jaws are custom-fitted to the shape of the workpiece. This reduces the risk of deformation, making it ideal for securing thin-walled, easily deformable parts—such as rings or sleeves—without causing flattening or distortion. Its high structural rigidity also enables it to withstand high cutting forces after clamping.

The new chuck can be easily integrated into automated or semi-automated production lines, allowing for fast and reliable clamping and unclamping through a single, simple operation. This reduces the technical requirements for operators and supports ZJK’s ongoing automation efforts.

Overall, the six-flap eccentric chuck offers excellent flexibility and cost-effectiveness, helping ZJK reduce clamping times and improve processing capabilities for complex components.

Irregular or bespoke workpieces—such as custom chassis, accelerator sleds, brazed micro-channel blocks, custom brackets, seals, and EMI shields—are becoming increasingly critical in AI servers, robotics and industrial automation. Parallel to the rapid expansion of global AI server market, particularly accelerator-server segment, the demand for irregular and bespoke components is accelerating.

The opportunity for suppliers of these specialized components is substantial, driven directly by surging AI-infrastructure investment and build-out of advanced cooling and precision-machining ecosystems. From an operational and technological standpoint, Computer Numerical Control (CNC) milling dominates the precision-machining revenue mix—the exact processes at the core of ZJK’s expertise. The Company’s new chuck technology, with enhanced gripping accuracy and versatility, positions ZJK at the forefront of manufacturing irregular components for AI-servers, robotics and industrial automation. This advancement reinforces the Company’s industry leadership while accelerating its market-share gains in this high-growth segment.

ZJK Industrial Co., Ltd. Triples Captive Screw Production Efficiency with New Semi-Automatic Equipment

ZJK announced the deployment of newly developed semi-automatic punching equipment for captive screws production. This advanced equipment significantly enhances automation in captive screw assembly, increasing production efficiency by more than threefold and reducing manual labor and related costs.

Traditionally, the production of captive screws involves assembling multiple components and manual punching, leading to low efficiency and inconsistent quality. Captive screws are composed of screws, housings, and springs, and require specialized tooling to prevent parts from dislodging before stamping and assembly. Additionally, the stamping mechanism’s working pressure must be adjusted to accommodate products of varying specifications. These challenges contribute to high manufacturing complexity and cost, despite the strong market demand for such fasteners.

To address these issues, ZJK invested in research and development to design a semi-automatic assembly system. The new system incorporates a circular workbench with a divider and an adjustable stamping mechanism, allowing seamless integration into automated assembly lines without manual intervention.

With this new equipment now operational, the Company has significantly enhanced its existing automated assembly capabilities for combined parts and opened up new possibilities for subsequent assembly processes. According to the Company, the new system has increased captive screw production efficiency by over three times and reduced required labor by 50%, further strengthening ZJK’s competitive edge in the fastener sector.

ZJK Secures Patent from CNIPA

ZJK Secures Patent for AI-Powered SMT Carrier Tape Inspection System

ZJK Industrial Co., Ltd. has been awarded a new patent by the China National Intellectual Property Administration (CNIPA) for its innovative image recognition-based inspection system for SMT (Surface-Mount Technology) carrier tape packaging.

Traditionally, SMT inspections are manual and slow. ZJK’s patented system automates the process using two high-precision image modules and real-time anomaly detection, eliminating the need for post-packaging manual checks. The system achieves near-100% accuracy in identifying missing components and other defects—significantly improving production speed, quality control, and customer satisfaction.

CEO Ning Ding stated: “This invention integrates seamlessly into production lines and marks a major step forward in eliminating inefficiencies in SMT inspections.”

ZJK sees strong long-term growth for this technology, citing rising global demand for automated quality control in electronics, EVs, aerospace, and industrial manufacturing. The system aligns with current global trends: smart factories, government-backed innovation incentives, and the push toward higher product reliability at lower costs.

This patent reinforces ZJK’s position at the forefront of intelligent manufacturing.

ZJK Reports Strong 2024 Growth Amid AI Boom

ZJK Industrial Co., Ltd. (NASDAQ: ZJK) has released its financial results for FY2024, showcasing a 30.13% revenue increase fueled by rising demand in AI infrastructure, electric vehicles, aerospace, and advanced electronics.

CEO Ning Ding highlighted strong sales across all product lines, with volume growth ranging from 7% to 50%. To keep up, ZJK expanded production capacity and invested in new equipment—leading to a 23.09% increase in gross profit, though gross margin dipped slightly to 35.88%.

ZJK also ramped up global expansion efforts, with selling and marketing expenses rising 169% and R&D up 20%, reflecting its commitment to innovation and global reach.

Notable highlights include the launch of new products at NVIDIA’s 2025 GPU Technology Conference and recognition as a Top 100 Enterprise in Shenzhen Pingshan.

ZJK aims to stay at the forefront of the next tech wave while reinforcing supply chain resilience.

ZJK Industrial Named Top 100 Business

ZJK Industrial Co. Ltd. (NASDAQ: ZJK), a leader in high-precision components for AI infrastructure, EVs, aerospace, and advanced electronics, has been recognized as one of the Top 100 Enterprises in Shenzhen Pingshan New District.

The award, presented by the local government, highlights ZJK’s strong contributions to regional economic and technological development. Known for its innovation, quality, and customer focus, ZJK continues to expand its footprint across global high-tech industries.

“We’re honored to receive this recognition,” said CEO Ning Ding. “It’s a testament to our team’s dedication and our ongoing commitment to innovation and sustainable growth.”

With this award, ZJK further solidifies its role as a key player in China’s advanced manufacturing sector.

ZJK Industrial Showcases Commitment to Sustainability and Innovation at XPRIZE Event in Los Angeles

Shenzhen, China – December 05, 2024 – ZJK Industrial Co., Ltd., a global leader in precision parts manufacturing, proudly announced its attendance at the XPRIZE event held in Los Angeles from October 25-27, 2024. This gathering of global innovators explored advancements in technology and sustainability, aligning with ZJK Industrial’s vision for driving progress through an innovative approach.

XPRIZE is a global non-profit organization that runs large-scale competitions to drive innovation, inspire breakthroughs that tackle the world’s greatest challenges, and advance a sustainable future in fields like climate, health, and AI. Its mission is “to inspire and empower humanity to achieve breakthroughs that accelerate an abundant and equitable future for all.”

At the event, ZJK Industrial engaged with other industry leaders to discuss the latest developments in AI technology, sustainable manufacturing practices and precision engineering. These interactions and new connections reinforce ZJK’s dedication to advancing Environmental, Social, and Governance (ESG) standards while staying at the forefront of technological breakthroughs.

“Attending the XPRIZE event aligns with ZJK’s dual commitment to both innovation and sustainability,” said Ning Ding, CEO at ZJK Industrial. “By embracing the latest technology and a sustainable approach, we aim to become a pioneer in precision manufacturing and exceed the demands of the industries we serve, such as AI, aerospace, and electric vehicles. Our goal is to create products that are as forward-thinking as they are environmentally conscious.”

ZJK Industrial is committed to leveraging the insights and relationships forged at the XPRIZE event to improve upon its processes, develop innovative solutions that enhance its product offerings, and increase its position as a trusted partner in the U.S. and global markets. By aligning innovation with sustainability, ZJK Industrial continues to deliver value to its partners and contribute to a brighter, more sustainable future.

Thank you for supporting ZJK's mission to provide innovative and sustainable precision parts solutions. Stay tuned for more exciting updates and announcements!

Disclaimer: These blogs may contain forward-looking statements that are subject to risks and uncertainties. Actual results could differ materially from those expressed or implied. The opinions expressed are those of the company and do not constitute a recommendation to buy or sell any securities or products.